Carego Wireless Ear Buds, Earbuds Bluetooth 5.3 Headphones 40H Playtime LED Display, HiFi Stereo Sound Waterproof in-Ear Earphones with Microphone for iPhone/Samsung/Android (Black)

20% OffAs their name implies, Rocker switches move back and forth while performing the ON/OFF operation. Here, one end rises, and the other is lower, housing the relevant operations.

It remains in the tilt position and moves either to the “on” or “off” site after exerting pressure on it. Rocker switches, while not new to the market, are a sophisticated type of switch. Engineers made the new switches on demand because of their working capabilities. Rocker switches are now one of the most popular panel-mount switches used in electric devices.

The article will provide you with these rocker switches’ main features and structures.

What are the main features of rocker switches?

- The switches are small in size and have a high capacity. The efforts of engineers enable them to make miniature on/off switches for the power supply on any equipment, like electrical appliances or the main power supply of your home.

- The operation button indicates On and Off, preventing anyone from making a mistake while pressing it, as large industries or factories depend on it.

Read more: Best gadgets for drummers in 2021

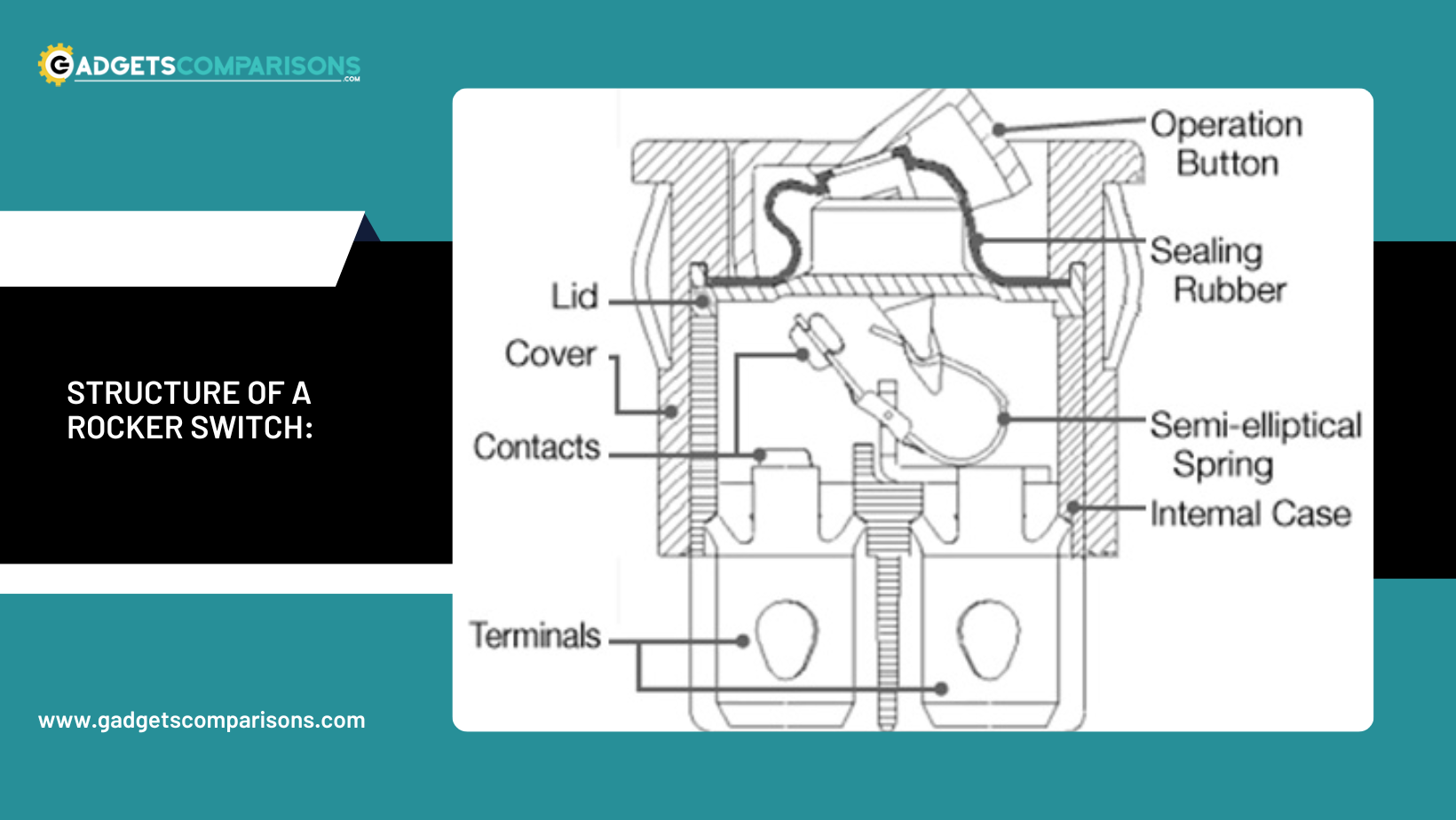

Structure of a rocker switch:

- Main button: The button that causes the On/Off operation to be performed by exerting force on it.

- It is the primary tool for completely sealing the button so that it remains protected from moisture and other objects, such as dirt or dust, that, upon entering, cause the switch to be damaged.

- A semi-elliptical spring is slightly elliptical. Its end is connected to a contact. When the operation button is pressed, the contact is transferred to a fixed one. Then, it applies much contact pressure to ensure a secure connection between the two. Contact welding is prevented when it is turned off due to an increase in the release of contact force.

- Case inside and lid: the parts that go into the switch mechanism. In the case, which also serves as a seal, are terminals, contacts, and semi-elliptical springs.

- Cover A resin portion covering the interior sealed casing. The sealing rubber is also fixed in place using it. In addition, it makes it simple to attach the switch within a square panel hole.

- Contacts and terminals: The fixed contact is created by affixing a contact to the end of one of the terminals.

Read more: 7 Cool Gadgets for Your Room

What are the common uses of rocker switches?

Rocker switches have a vast range of applications in the field of electricity. Most light switches, including the On/Off feature, use rocker switches. Others may also include the appliances or even vehicles that we equip daily.

It is impossible if you are living in the twenty-first century and have never found rocker switches on your wall sockets or extension cord lids.

Some common examples of such applications include.

- Household appliances

- Hydraulic systems

- Fuse circuits

- control panel and power supplies

- Machinery and medical tools

- HVAC systems

Read more: 7 Best Gadgets For Lawyers

Some frequently asked questions.

The four main types of switches include;

- Single pole single throw

- Single pole double throw

- Double pole single throw

- Double pole double throw

Compared to a single pole switch, a 3-way switch is more significant and features three screw terminals for wiring connections in addition to the ground. From one switch to the next, two of them accept traveler wires. One switch is linked to the hot supply wire for the third terminal, while the other switch is connected to the light.

Rocker switch connectors are typically inexpensive and come in various sorts and combinations. They are easily installed, accessible, and reasonably priced essential components.

Related Links:

- https://en.wikipedia.org/wiki/Switch /By Wikipedia

- https://en.wikipedia.org/wiki/Multiway_switching /By Wikipedia

- https://en.wikipedia.org/wiki/Light_switch /By Wikipedia

- https://www.wikihow.com/Install-a-Toggle-Switch /By Wikihow

- https://www.wikihow.com/Wire-a-Wall-Switch /By Wikihow

- https://www.wikihow.com/Wire-a-Double-Switch /By Wikihow

- https://www.wikihow.com/Replace-a-Light-Switch /By Wikihow